Nik Polyakov

Engineering Portfolio

Mechanical Engineering ('28) student @ Boston University, double-concentrating in Machine Learning and Sustainability.

Leveraging the interdisciplinary environment of Kilachand Honors College and the city of Boston to deepen my understanding of the societal challenges I aim to address through engineering. By integrating mechanical design and software, I can develop intelligent and adaptable systems, ensuring they meet the evolving needs of the world.

Click on project names to learn more

Engineered a fully parametric off-road racing vehicle assembly, enabling real-time animation and automatic recalculations of suspension and steering geometry based on toe, camber, and compression variables. This streamlined iteration, reducing design time. Led the front hub carrier design, a component machined with precision 3-axis HAAS milling to withstand upwards of 4kN of force while holding the front wheels and allowing for high-range at high speeds.

SolidWorks

HSMWorks Computer-Aided Manufacturing

Onshape Enterprise

ANSYS Finite Element Analysis

Welding

Siemens NX Generative Design

CNC Milling

SolidWorks HSMWorks Computer-Aided Manufacturing Onshape Enterprise ANSYS Finite Element Analysis Welding Siemens NX Generative Design CNC Milling

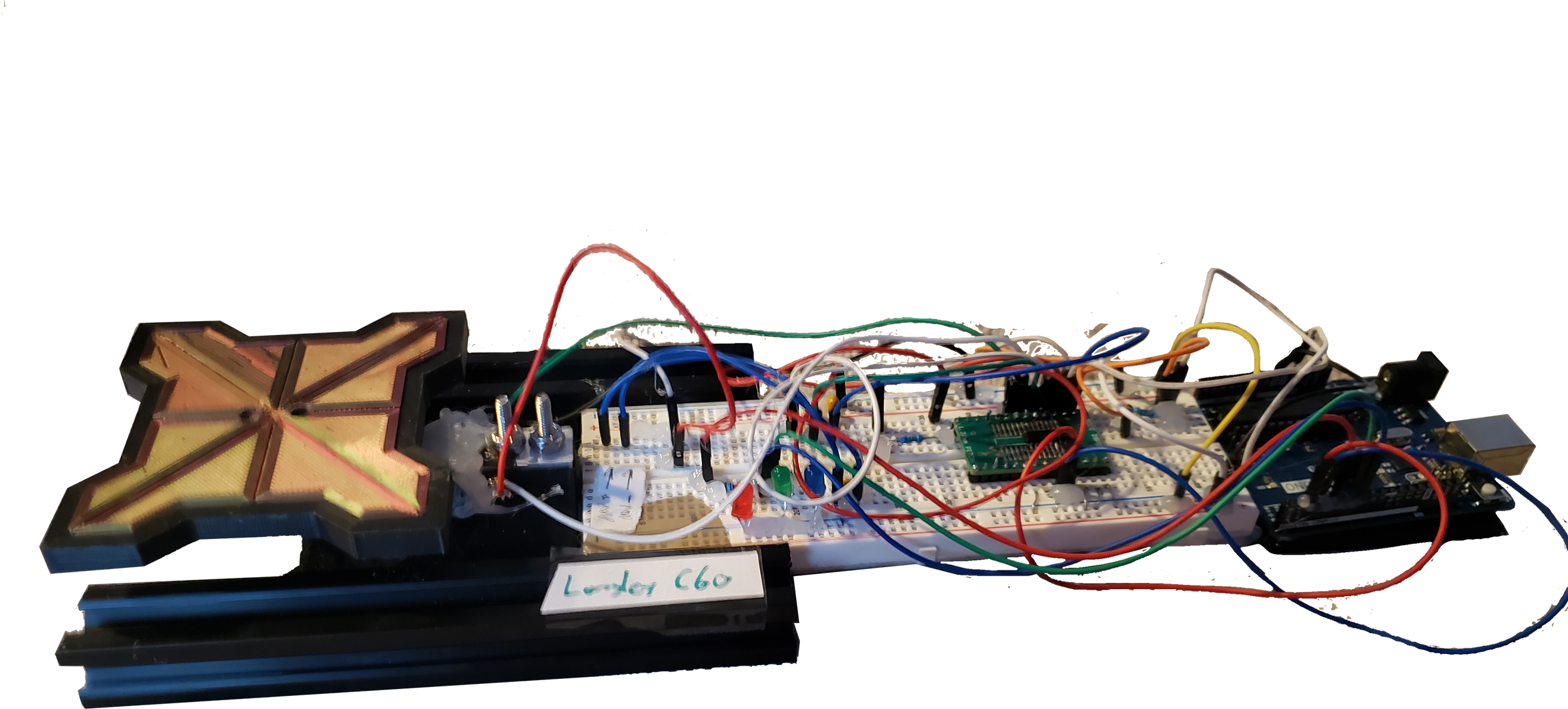

Designed and built a custom mass-sensing probe from scratch, using a homemade load cell, HX711 amplifier, and Arduino for +/- 1-gram precision for 30-1000g samples. Reverse-engineered the HX711 by melting off the microprocessor (due to competition rules) and reconstructing its resistor-capacitor network to simulate the original circuit. Developed a custom load cell by adhering strain gauges onto an aluminum block, amplifying the microscopic strain in the cell by using a Wheatstone bridge configuration. Implemented an auto-calibration routine with known weights and applied linear regression to refine accuracy across varying mass ranges. Awarded 15th out of 7800+ teams at the 2023 Science Olympiad National Tournament.

Circuit Design

Material Science

Arduino

Soldering

Circuit Design Material Science Arduino Soldering

Designed and validated critical mechanical systems for Argo, a liquid bipropellant rocket targeting a record university launch altitude. Developed avionics bay and separation/recovery system development, engineering for extreme loads and mission-critical reliability. Delivered FEA&hand-calc-validated structures to 5-ton compression, integrated fluid routing for dome exhaust and servicing, and sealed recovery assemblies rated for 7 g acceleration and high-altitude deployment.

Design for Manufacture

Finite Element Analysis

Thermal design

Soldering

Fluid routing

Design for Manufacture Finite Element Analysis Thermal design Soldering Fluid routing

Designed and built a structurally optimized, modular nozzle mounting fixture for engine testing, ensuring precise thrust measurements and supporting next-generation liquid propulsion advancements. Developed a waterjet-cut sheet metal jig in SolidWorks, allowing variable nozzle positioning while eliminating torque on the thrust-measuring load cell. Performed structural analysis in SolidWorks FEA, validating integrity under thrust vectoring conditions. Calculated preloads for bolted connections to ensure stability during engine operation. Designed a hybrid rocket nozzle, optimizing expansion ratios and thermal resistance for efficient combustion. Machined engine components, mounting brackets, and nozzle retainers using CNC milling and manual lathe operations to meet precise tolerances. Contributed to RPG’s goal of becoming the first university team to launch a liquid-fuel rocket into space.

SolidWorks

Finite Element Analysis

Fluid Systems

Material Science

Milling

Tolerancing & GD&T

SolidWorks Finite Element Analysis Fluid Systems Material Science Milling Tolerancing & GD&T

Designed and built a supercapacitor-powered electric dragster for the Rachel Carson Middle School engineering program, replacing the CO₂ propulsion system with a reusable, modular design. Developed a transplantable control box in Fusion 360, integrating motor drivers and a Bluetooth-enabled Arduino for seamless interchangeability between student-built chassis, reducing hardware costs. Engineered a prototype aerodynamic shell with a diffuser, rear wing, side skirts, canards, and a front splitter to generate downforce and enhance high-speed stability. Designed a custom Bluetooth app to enable simultaneous remote triggering for racing. Powered by a 16V, 100F supercapacitor bank capable of delivering peak currents exceeding 30A, enabling rapid acceleration. Validated aerodynamic performance using SimScale CFD, demonstrating drag reduction and stability.

Circuit Design

Fusion 360

Arduino

Computational Fluid Dynamics

Circuit Design Fusion 360 Arduino Computational Fluid Dynamics

At the National Institute of Standards and Technology (NIST), I developed standardized methods to characterize LiDAR sensor accuracy for robotics applications. Using a combination of MATLAB and Python, I automated point cloud analysis across varying distances and incident angles, fitting planes via Principal Component Analysis (PCA) to measure noise and residuals. The workflow cropped each scan to the beam footprint, aligned data using eigenvectors, and generated residual heatmaps and statistical reports. These results revealed how beam divergence and surface geometry impact precision, forming the foundation for a repeatable benchmarking framework that enables fair comparison of LiDAR systems across manufacturers.

Python

Matlab

Scikit Learn

Optics/Sensing

Principal Component Analysis

LiDAR

Python Matlab Scikit Learn Optics/Sensing Principal Component Analysis LiDAR

Developed a Python-based analysis utilizing H3 spatial indexing to align US Census population density data with NOAA vegetative health datasets, overcoming discrepancies in data point spacing. Plotted and visualized adjusted datasets over the same land area for a consistent comparison of urban development’s impact on local climate. Highlighted key trends in green space distribution, urban planning styles, and climate health correlations. Created an interactive visualization showcasing climate health relative to population density: bit.ly/3EwNViI.

Python

H3 Indexing

Environmental Analysis

Optics/Sensing

Python H3 Indexing Environmental Analysis Optics/Sensing

Conducted X-ray diffraction (XRD)-inspired analysis for ME306 using an XRD-parallel setup with RGB wavelengths to evaluate the crystallographic structure of various materials focusing on lattice parameters, and crystallinity. Processed diffraction data using MATLAB to generate accurate diffraction patterns, identifying key peaks corresponding to specific material phases. Utilized Rietveld refinement techniques and least-squares regression to extract quantitative information on crystal structure and expiremental uncertainty.