Plastic recycling

for 3d printing

-

Design and manufacture an automated system that converts on-campus plastic waste into 3D printer filament

Perform testing on various washing/shredding/desiccation processes to select target conditions

Contribute to the community’s understanding of PLA recycling

Allow for PLA plastic to stay in BU printing labs until taken out in a permanent print

-

Co-founder & design lead - wrote the grant proposal for the Institute for Global Sustainability, led design decisions about mechanical system architecture, manufactured subsystems

-

October 2025 - present

-

Onshape

Design for Manufacture

Design for Assembly

Sustainability

Polymer processing

Computer aided machining

Fluid systems

-

In-progress

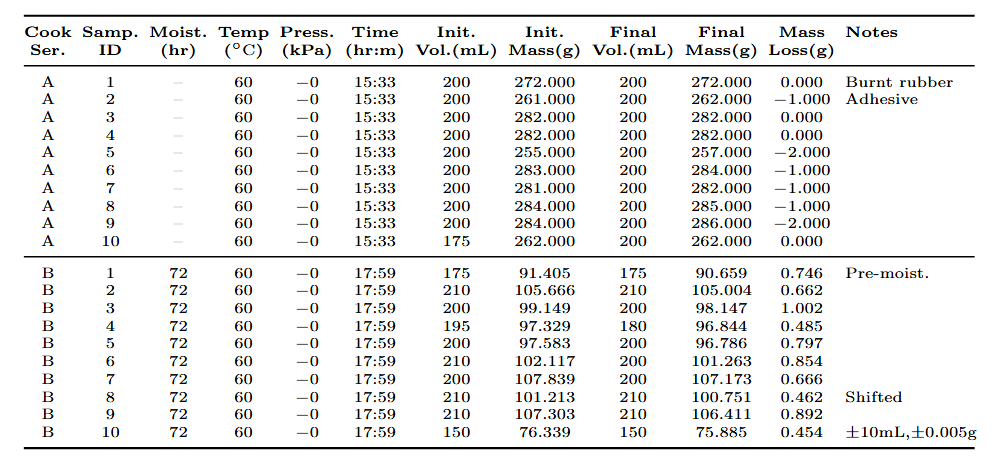

Conducted tests on desiccation of moist PLA chips in varying temperature and pressure conditions to determine optimal system conditions

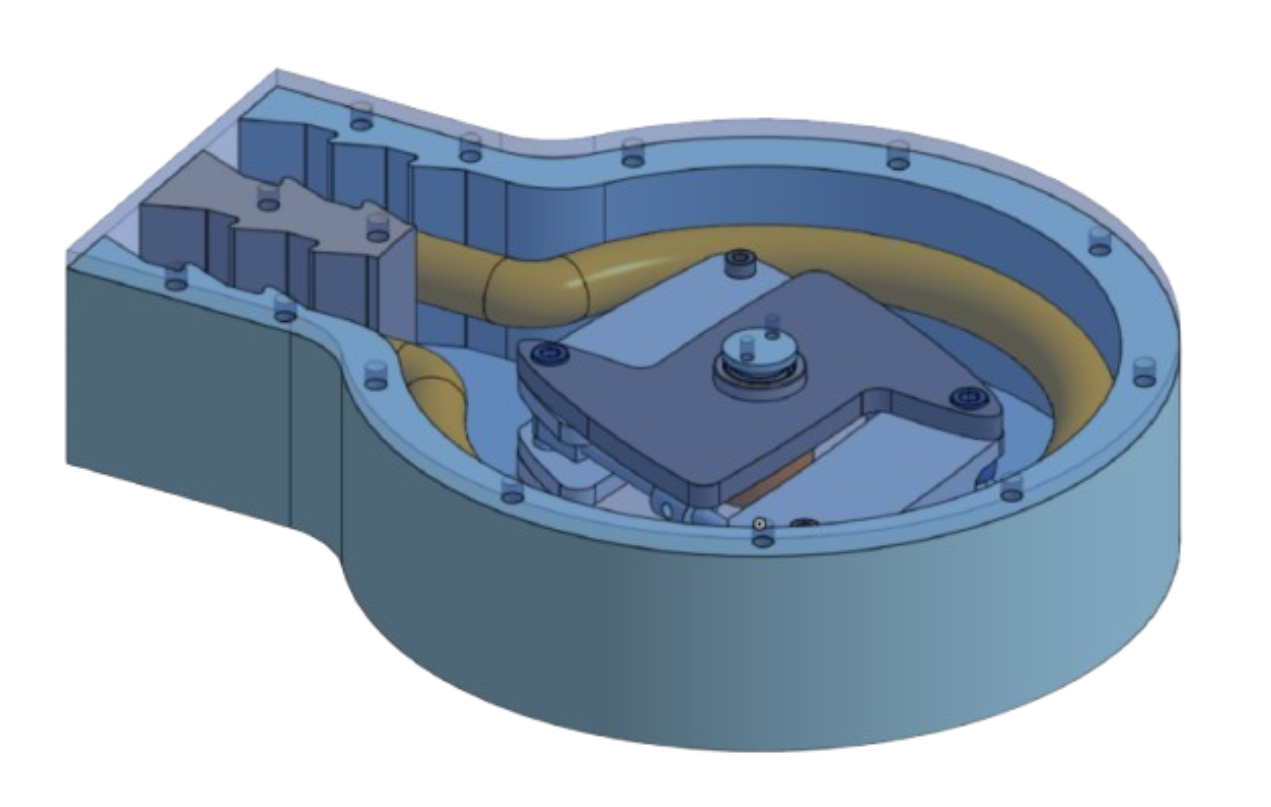

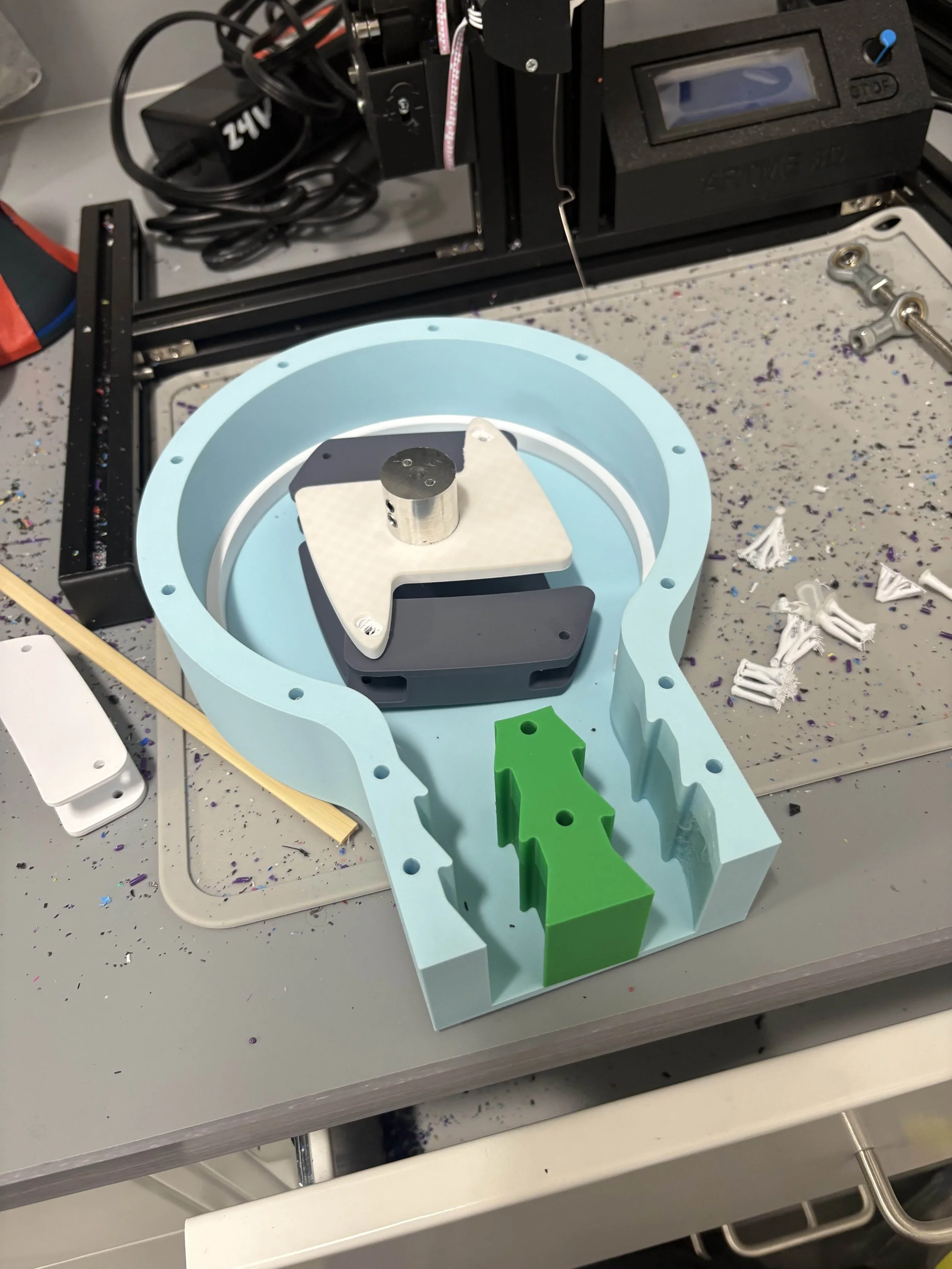

Designed and built working peristaltic pump to density-sort egressing plastic from the ultrasonic washer

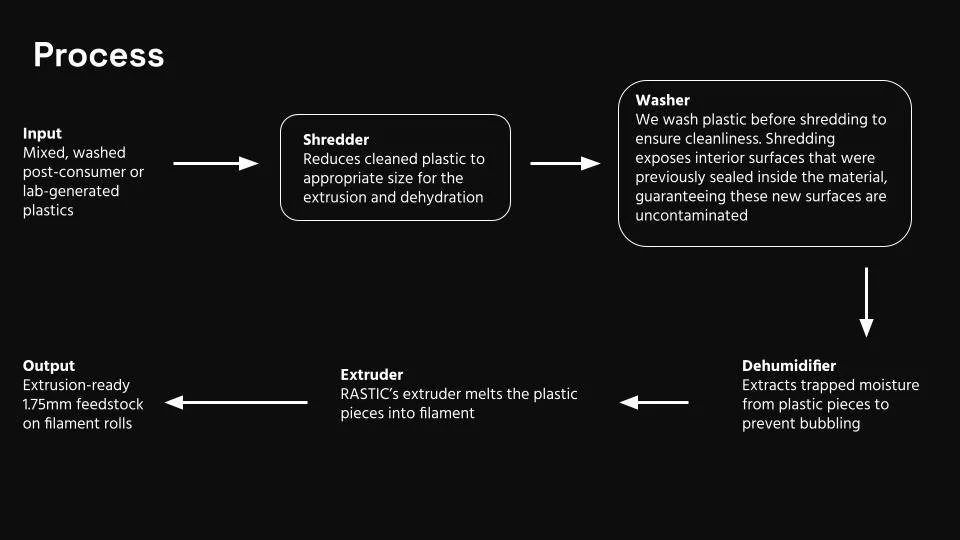

Objective: take moist, dirty plastic, convert it into usable 3D printer filament and heat-pressed sheets.

To find optimal conditions for each subsystem as well as their order, we follow the process:

Overview possible washer/dryer/dehumidifer setups and order → evaluate the efficacy and conditions of each through standardized testing → construct prototypes → integrate the system into an automatic throughput

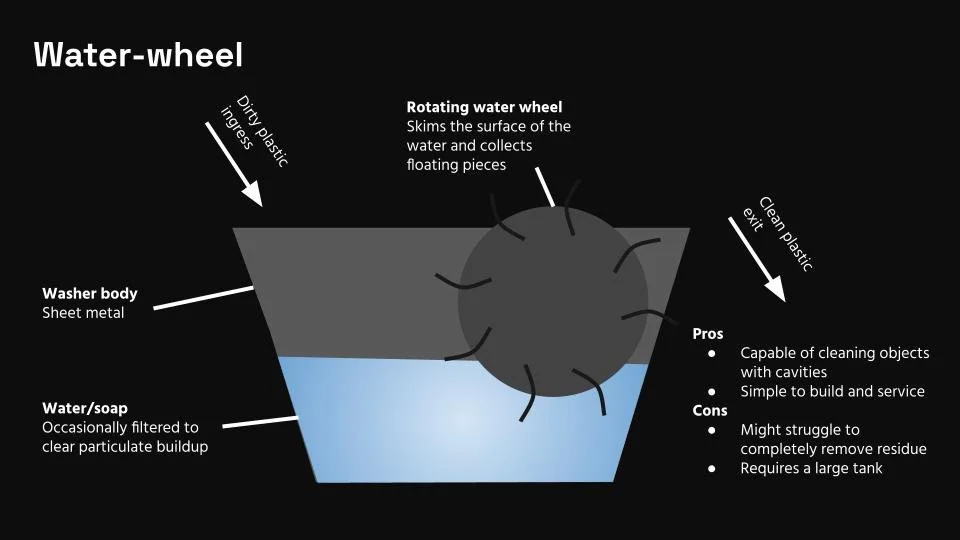

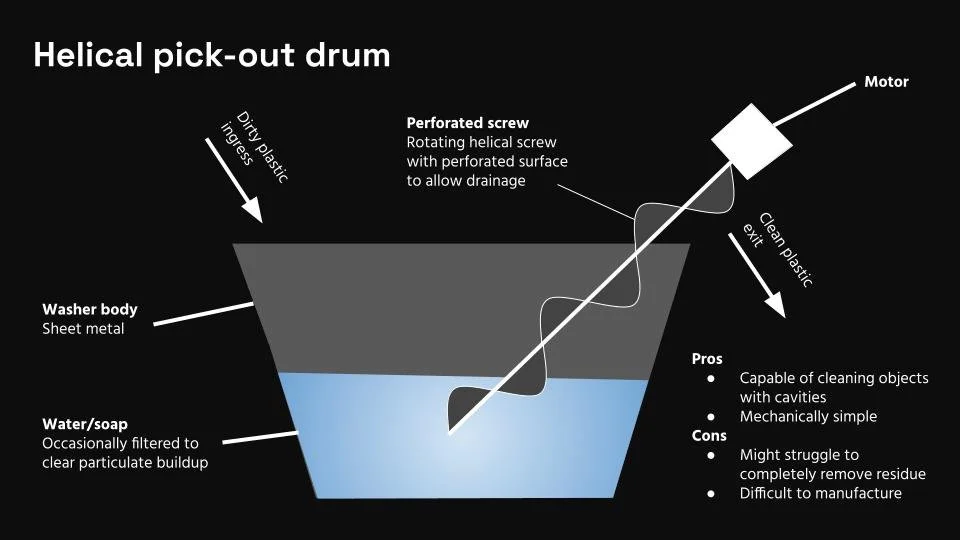

Washer candidates

We selected a shred-first, wash-second process because shredding increases surface area and exposes internal cavities that are otherwise difficult to clean.

Because washed plastic will then contain trapped moisture, the water will bubble during extrusion and cause poor print quality. Thus, a dehumidifer is implemented following the washer.

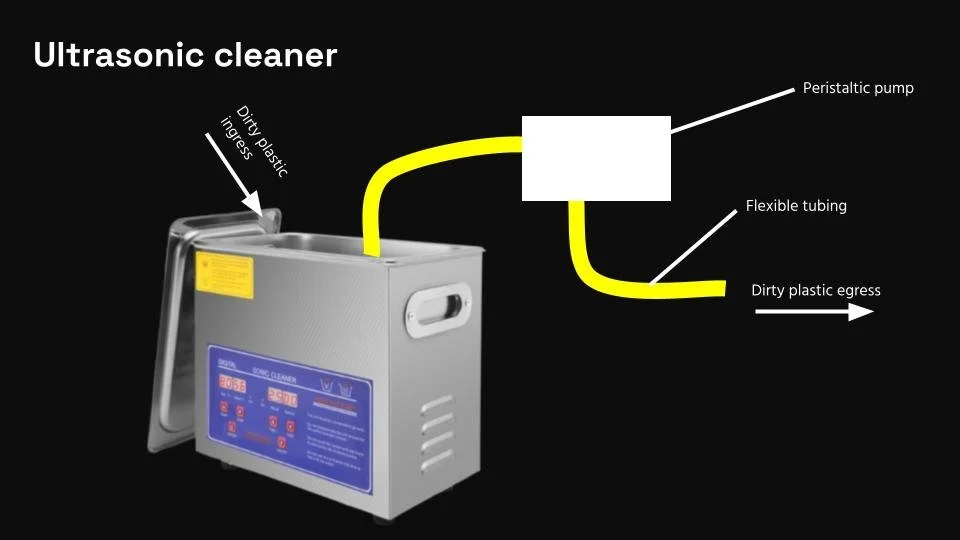

We are first expirementing with an ultrasonic cleaner setup.

Through cavitation with a specialized cleaning fluid, these cleaners able to effectively remove residue off all surfaces.

To remove heavier particulates (such as metal) that accumulate on recycled plastic, density sort will be used and plastic will be filtered out with a peristaltic pump

Peristaltic pump design, it uses springs of varying compression to adjust how much the plastic slurry is compressed

Drying systems

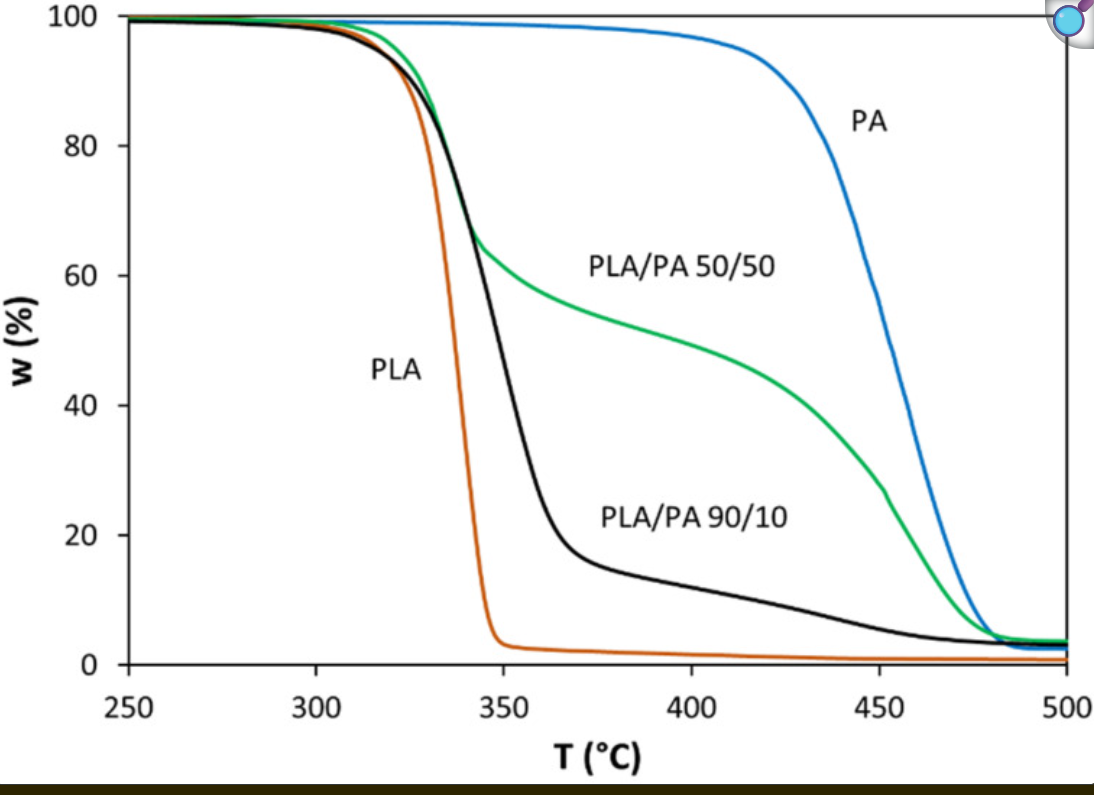

PLA polymers don’t degrade until relatively high temperatures to water boiling.

Thus we expiremented with reduced pressure dehydration, and also full heating at standard pressure.

Our hypothesis is reduced pressure can help outgas trapped bubbles in the flakes.

Results confirm that thermal dehydration at 60 ◦C effectively removes absorbed moisture without observable thermal degradation. The project will design a pressure-sealing vessel (vacuum- compatible chamber) that can both heat and desiccate plastic safely with instrumentation (pressure, temperature, time logging) and appropriate safety features (relief strategy, interlocks, and material compatibility).

Early designs used a rotating rear door that uses threads to clamp as it closes. A chamber of silica beads in the intake desiccates incoming heated air.

To reduce mechanical complexity and load on the hinge, designs in current development will use sliding clamps.

Complete testing to determine optimal desiccation conditions

Evaluate the efficacy of the density-based sorting method

Purchase and integrate a prebuilt shredder into the workflow

Design and construct the desiccator system

After validating each subsystem, integrate the full process with the STM32 control architecture and operate within fume hood constraints

Implement a single-color rapid-prototyping stream across BU labs with a target of reducing new filament purchases on campus by 60%